High-precision detection of micro-deformations resembling wrinkles occurring on the surface of the film is possible!

Measure micro-deformations of film with high precision in-line! It can measure micro-deformations of 10μm over a wide range of 400mm all at once!

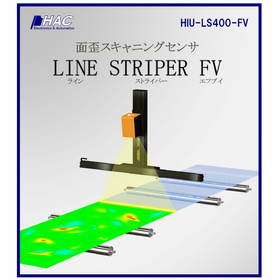

The surface distortion scanning sensor "LINE STRIPER FV" can measure minute distortions in film with high precision in-line! Using our uniquely developed MR method (Mesh Reflection), we measure distortion by projecting slit lighting onto the target object and calculating curvature from the amount of distortion in the lighting. This method amplifies distortion using the principle of optical leverage, as used in AFM (Atomic Force Microscopy), allowing for more precise measurements compared to pattern projection type 3D measurement devices. 【Features】 ■ High Sensitivity Capable of measuring minute distortions of several micrometers that are difficult to measure with conventional 3D measurement devices. ■ Wide Range Continuous in-line measurement over a wide area of 400mm. ■ Visualization Measurement results are displayed as curvature color contour maps, making minute distortion areas immediately clear! *For more details, please refer to the PDF or feel free to contact us.

- Company:八光オートメーション

- Price:Other